Mitigate Machine Downtime with Preventive Maintenance in D365 for SCM

Posted on: July 12, 2021 | By: Jarrod Kraemer | Microsoft Dynamics AX/365, Microsoft Dynamics Manufacturing

As a manufacturer you know all too well that maintenance on equipment is a necessary evil. However with the proper tools and schedule in place, the maintenance can be planned verses a more expensive “unplanned” event on already scheduled production line or machine. Preventive maintenance is a discipline involving planned maintenance jobs, for example, regular service, calibration, and inspections. In D365‘s Asset Management, you can create maintenance plans and set them up on assets and functional locations. Maintenance rounds can be set up on functional locations. Maintenance plans and maintenance rounds on functional locations are active for the assets currently installed at the location. Instead of setting up maintenance plans on assets, or setting up maintenance rounds on functional locations, you can create maintenance rounds that include multiple assets on which you need to perform related types of maintenance jobs in the same work routine. This allows you to select a number of assets for one maintenance round, which are not installed on the same functional location.

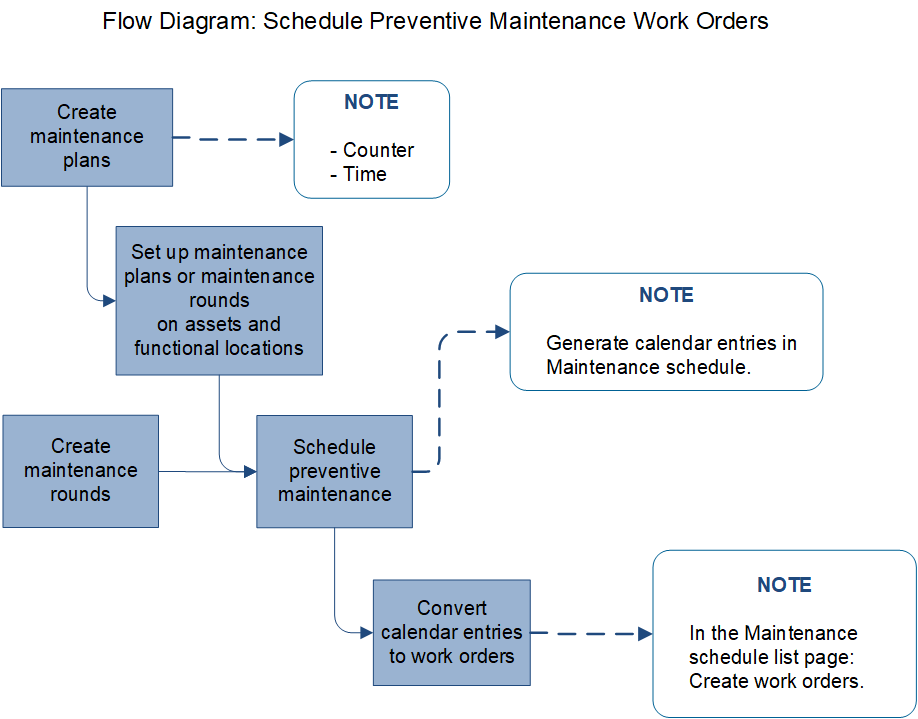

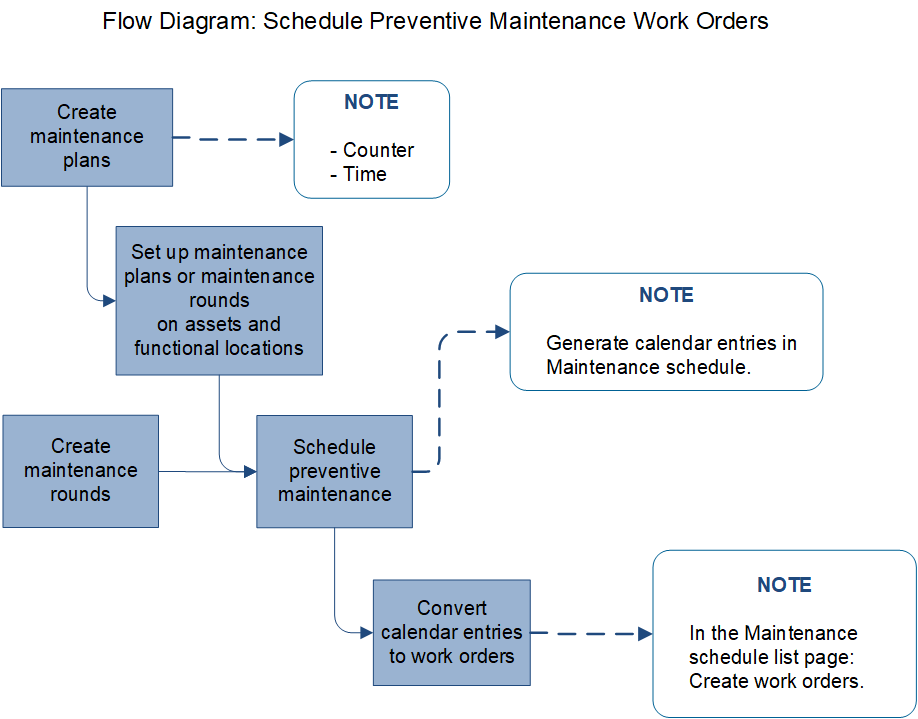

The illustration below provides an overview of the workflow from creating maintenance plans and maintenance rounds to creating work orders for assets, based on those maintenance plans and maintenance rounds. Maintenance plans are used for preventive and reactive maintenance on individual assets, while maintenance rounds are used for preventive maintenance on a group or a set of assets. Maintenance plans and maintenance rounds are both used for generating work order proposals. Work order proposals are saved as maintenance schedule lines, which can be bundled and converted into work orders.

Maintenance Plans

A maintenance plan defines when a pre-planned preventive maintenance job is to be carried out on an asset. Maintenance plans can be related to assets, asset types, functional locations, or functional location types, but first, you create the maintenance plans to be used in your company. A maintenance plan can have multiple maintenance plan lines. Maintenance job type and interval are specified on the maintenance plan line. There are two types of maintenance plan lines:

Maintenance plan lines of type “Time” are used for recurring planned maintenance based on a fixed time interval. Maintenance plan lines of type “Counter” are used for planned maintenance or reactive maintenance based on asset counter registrations. A maintenance plan may include several maintenance plan lines of both types.

Maintenance Rounds

In Asset Management, you can create maintenance rounds for various assets, on which you need to carry out a similar task at regular intervals. For example, lubrication jobs or safety inspection jobs need to be carried out on a number of machines within the same intervals. The first step is to create a maintenance round, including assets that require the same form of maintenance job. Next, you schedule the maintenance rounds. When you have completed the maintenance rounds schedule, you can see all the job records relating to the round in the All maintenance schedule and Open maintenance schedule lines.

Maintenance Schedule

The maintenance schedule contains a list of all the expected preventive maintenance plans, maintenance requests, and maintenance rounds to be carried out. Some schedule lines may have been converted to work orders.

The four maintenance schedule views are slightly different, depending on which maintenance schedule lines you want to see.

- All maintenance schedule: All maintenance schedule lines are shown.

- My asset schedule: All maintenance schedule lines containing assets installed on functional locations to which you are related as a worker (set up in Maintenance workers and worker groups) are shown in this list.

- Open maintenance schedule lines: Maintenance schedule lines with status “Created” – meaning they have not yet been converted to a work order or discarded – are shown in this list.

- Open maintenance schedule pools: Maintenance schedule lines related to a work order pool are shown in this list.

Next Steps

If you are interested in learning more about preventive maintenance as well as maximizing the use of Microsoft Dynamics 365 for Finance and Supply Chain Management contact us here to find out how we can help you grow your business. You can also email us at info@loganconsulting.com or call (312) 345-8817.

Related Posts

-

Posted on: April 22, 2024

Managing expenses efficiently in a dynamic business environment is important for maintaining budget control and ensuring financial compliance. Microsoft Dynamics...

Read More ›

-

Posted on: April 17, 2024

In today's world, technology is breaking new ground all the time, making it important to use artificial intelligence (AI) in...

Read More ›