Demand Forecasting in Dynamics 365 Supply Chain Management Overview

Posted on: April 4, 2022 | By: Guy Logan | Microsoft Dynamics AX/365, Microsoft Dynamics Manufacturing

According to Feeding America, each year 108 billion pounds of food is wasted in the United States. That equates to 130 billion meals and more than $408 billion in food thrown away each year. This is nearly 40% of all food in America is wasted! By using demand forecasting and predictive analytics to closely monitor inventory levels, it is possible to reduce food wastage without ending up with bare shelves.

By leveraging advanced demand forecasting software such as the one provided in Dynamics 365 Supply Chain Management, independent demand from sales orders and dependent demand can be used to predict at any decoupling point, the boundary between make-to-order (MTO) and make-to-stock (MTS), for customer orders. The enhanced demand forecast reduction rules provide an ideal solution for mass customization.

This blog describes ways your company could use demand forecasting in Dynamics 365 Supply Chain Management for increased efficiency in the food and beverage industry.

Key features of demand forecasting

Here are some of the main features of demand forecasting:

- Generate a statistical baseline forecast that is based on historical data.

- Use a dynamic set of forecast dimensions.

- Visualize demand trends, confidence intervals, and adjustments of the forecast.

- Authorize the adjusted forecast to be used in planning processes.

- Remove outliers.

- Create measurements of forecast accuracy.

Major themes in demand forecasting

Three major themes are implemented in demand forecasting:

- Modularity – Demand forecasting is modular and easy to configure. You can turn the functionality on and off by changing the configuration key at Trade > Inventory forecast > Demand forecasting.

- Reuse of the Microsoft stack – Machine Learning, which is part of the Microsoft Cortana Analytics Suite, lets you quickly and easily create predictive analysis experiments, such as demand estimation experiments, by using algorithms R or Python programming languages and a simple drag-and-drop interface.

- Forecast reduction at any decoupling point – Demand forecasting in builds on this functionality, which lets you forecast both dependent and independent demand at any decoupling point.

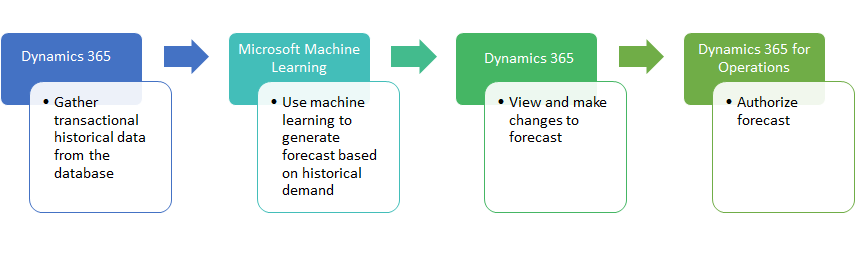

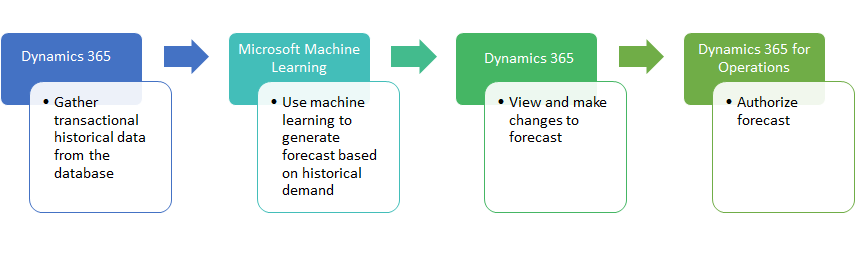

Basic flow in demand forecasting

The following diagram shows the basic flow in demand forecasting.

Demand forecast generation starts in Supply Chain Management. Historical transactional data from the Supply Chain Management transactional database is gathered and populates a staging table. This staging table is later fed to a Machine Learning service. By performing minimal customization, you can plug various data sources into the staging table. The data sources can include Microsoft Excel files, comma-separated value (CSV) files, and data from Microsoft Dynamics AX 2009 and Microsoft Dynamics AX 2012. Therefore, you can generate demand forecasts that consider historical data that is spread among multiple systems. However, the master data, such as item names and units of measure, must be the same across the various data sources.

If you use the Demand forecasting Machine Learning experiments, they look for a best fit among five time series forecasting methods to calculate a baseline forecast. The parameters for these forecasting methods are managed in Supply Chain Management.

The forecasts, historical data, and any changes that were made to the demand forecasts in previous iterations are then available in Supply Chain Management.

You can use Supply Chain Management to visualize and modify the baseline forecasts. Manual adjustments must be authorized before the forecasts can be used for planning.

Next Steps

If you are interested in learning more about demand forecasting in Microsoft Dynamics 365 for Supply Chain Management, contact us here to find out how we can help you grow your business. You can also email us at info@loganconsulting.com or call (312) 345-8817.

Related Posts

-

Posted on: February 25, 2026

Industrial and manufacturing organizations operate in a regulatory minefield. Indirect tax (sales tax, VAT, GST), SOX-style internal controls, cross-border trade...

Read More ›

-

Posted on: February 23, 2026

In industrial organizations, order fulfillment isn’t a single handoff. It’s a chain reaction. Configured products. Long lead times. Partial shipments....

Read More ›