Reviews and corrects ledger-to-subledger alignment in D365 by fixing posting configurations, inventory profiles, reconciliation logic, GL mapping, and critical reporting procedures.

Supplier Schedules: Planning Parameters and Their Impacts

Posted on: August 8, 2021 | By: Andrew Hall | QAD Business Process, QAD Distribution, QAD Manufacturing

In QAD, Supplier Schedules are a powerful and efficient method of communicating demand and purchasing requirements to suppliers in an automated fashion. However, to get the most out of this functionality, it is important to understand how to setup the planning parameters such that the Supplier Schedule releases align with the desired inbound material flow. This blog will address the key fields in the Supplier Schedule that impact the status, quantity, and dates contained on your releases.

All the below values are established at the Order Line Item Data level in Supplier Scheduled Order Maintenance.

Firm Days: This field determines the number of days from the date of release that quantities on the release are firmed. Once firmed, the update from MRP cannot change either the date or the quantity. You should review your action messages and make changes manually if, for example, an expedite is needed.

Std Pack Qty: To ensure that all quantities on your releases fit with a standard pallet or box quantity, enter that value here and the update function will round up to a multiple of this value.

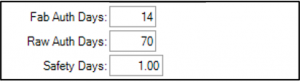

Fab Auth Days: If your agreement with the supplier authorizes them to hold a certain number of days of demand of the completed item in inventory as a buffer against unforeseen demand increases, enter that value here.

Raw Auth Days: If your agreement with the supplier authorizes them to hold a certain number of days of demand of the material requires to make this item in inventory as a buffer against unforeseen demand increases, enter that value here.

Safety Days: If you want the material to arrive on site earlier than the exact date that MRP has calculated, then enter the number of days early you want the material to arrive. Note: this value is specific to this Scheduled Order line versus the general Safety Days value in the Item’s planning data that MRP utilizes.

Ship Delivery Pattern Code: Set the Ship Delivery Pattern to select the specific dates that you want material from this scheduled order item to arrive at your receiving dock. MRP due dates will be back scheduled to align with the selected pattern.

Transport Days: This field will determine what the supplier sees on the release. If this value is 0, then the release will display the date material needs to arrive at your dock (i.e., required date). If this value is greater than one, then the release will calculate the date the supplier needs to ship the material by back scheduling the ship date from the required date and it will specifically be noted to the supplier as their ship date.

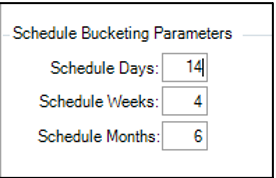

The Schedule Bucketing Parameters determine how the release displays individual days, weeks, and months.

Schedule Days: This determines the number of days, from the date of the release, that will be individually noted on the release. We typically recommend having the daily buckets number be the same as the Firm Days setting.

Schedule Weeks: This is the number of weekly buckets that will appear on the release beginning immediately following the last day that is bucketed individually based on the above setting. All quantities within each week will be summed and displayed using the first day of the week.

Schedule Months: This is the number of monthly buckets that will appear on the release beginning immediately following the last week that is bucketed individually based on the above setting. As with the weeks above, all quantities within the month will be summed and shown as one line on the release.

Next Steps

If you are interested in learning more about supplier schedules and/or maximizing the use of your QAD system, contact us here to find out how we can help you grow your business. You can also email us at info@loganconsulting.com or call (312) 345-8810.